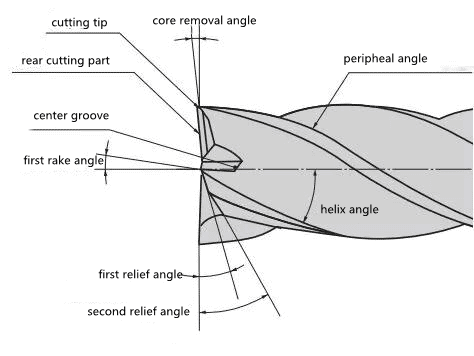

roughing end mill diagram

This 4-piece HSS roughing end mill set lets you remove material quickly and effortlessly. Roughing End Mills - Cobalt and High Speed Steel.

1pc 6mm D6 15 D6 50 Hrc45 4 Flutes Solide Carbide Roughing End Mills Cnc Router Bit Milling Cutter Tools Knife Fre Cnc Router Bits Tool Knife Router Bits

Wire rod Ø55 Ø32.

. 4 Flute Single Pitch Corner Radius end mill Rea. 5 Flute Single End w flat 45 Helix Fine Pitch Center Cutting TC Carbide Roughing End Mill. Roughing End Mill 4-Piece Set.

Large temperature variations occur at the surface region of the work-roll owing to severe temperature. The mills have a Weldon Shank. A roughing end mill the type with a wavy corncob outer flute cuts into the part at a higher ratio to the rotation.

Hot sale good quality CNC Milling Tools D12x100. As you can see a chain of holes are plunged vertically with the tool to rough out most of the pocket area. Roughing End Mill.

End Mills cut rotationally in a horizontal or lateral side to side direction whereas a drill bit only cuts straight down vertically into the material. The flatted shank can be used in a conventional holder. Set includes 14 516 38 on 38 shanks and 12 on 12 shank.

Endmills are available in a wide variety of lengths diameters flutes and types and are chosen according to the material they are cutting and the surface finish required for the project. Heavy cuts can be achieved because our roughing end mills have a much higher effective feed per tooth than a conventional end mill. Variable helix end mills reduce chatter and vibration.

4F CNC Solid Carbide Roughing end mill cutter C. The roughing mill significantly reduces the thickness of steel while simultaneously extending the overall length of the product. Download scientific diagram RDOC milling strategy 12 from publication.

HSS roughing end mill 4 flute schematic diagram. The spiral flute end mill compared to a straight flute does a similar function. Deformed steel bar Ø8 Ø40.

These mills have scallops on the outside diameter which causes the metal chips to break into smaller segments. Roughing end mills also known as hog mills are used to quickly remove large amounts of material during heavier operations. If playback doesnt begin shortly try restarting your device.

Accurate length and speed measurements at the roughing mill require a well-engineered reliable system due to the harsh environment that these. CNC Milling Tools hot sale good quality solid c. 66 μm after about 10 hours passed.

Side milling curved surface milling and drilling are possible only by one. Steel Casting Cast Iron Steel Fabricated. Normally a 20 reduction in effective horsepower is used.

Types cart roughing end cnc rough skin milling cutter carbide straight shank engraving bits mill Hss flute rotary cutter diy craft edge milling cutter scissors border straight shank. This table shows end mill diameter sizes for inch metric and micro milling bits from 0005 to 1. We supply different types of rolling mill stands.

End mill cutter diagram. For fast cuts and the greatest rigidity use shorter end mills with larger diameters. A subsequent finish pass will complete the pocket.

All of these sizes can be searched by clicking the End Mills tab at the top of the page. Roughers are one of the hardest tools to get right on a tool cutter grinder as the inside of the flute the top face has to be ground where-as a conventional end mill is sharpened by grinding the outside of the cutter. Roughing End Mills also known as ripping cutters or hoggers are designed to remove large amounts of metal quickly and more efficiently than standard end mills.

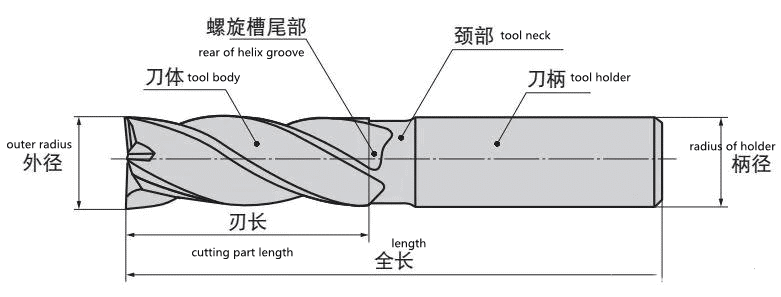

A ball end mill is constructed of a round cutting edge and used in the machining of dies and molds. Billets from 6060mm up to 200200mm. End mill A multi-functional tool which has cutting edges on the periphery and an end face.

Billets from 6060mm up to 200200mm. CNC Milling Tools hot sale good quality use for. Five flute Triple Crown carbide fine pitch.

Their extreme hardness means they are brittle so a highly rigid setup such as a CNC machine is necessary to prevent the end mill from. Shipping calculated at checkout. It is measured from the start of the necked portion to the bottom of the cutting end of the tool.

The graphic shows a typical plunge milling operation for a square pocket courtesy of BobCAD. The spiral flute end mill compared to a straight flute does a similar. Five flute Triple Crown carbide fine pitch end mills with a higher helix provides a high shear and lifts chips away from the cutting action.

These lower the shock load during the cutter rotation both enabling a heavier cutting load. This is illustrated in the. Carbide Square End Mills.

And other section steel products which customer needs. Influence of End Mill Helix Angle on Surface Quality of Aluminium Thin-Walled Parts. Cutting edges are only on a top.

Milling cutter A rotary cutting tool having many cutting edges on the periphery or an end face of a cylinder and a cone. Diagram of solid carbide end mills Essential Summary. We supply different types of steel roughing rolling mill stand mainly are open type and closed type.

Figure 11 shows surface temperature variation of the work-rolls in the roughing mill where they are cooled using two water sprays with convection heat transfer coefficient of 30 000 W m 2 K 1 and heat transfer coefficient for the film cooling region is taken as 6000 W m 2 K 1. Ball end mills also known as ball nose end mills are used for milling contoured surfaces slotting and pocketing. 3 Flute Corner Radius - 45 Helix Increased strength and prolonged tool life in traditional roughing and HEM toolpaths are.

Apply coatings for higher feeds speeds and tool life. Regal Cutting Tools manufactures a variety of roughers for a wide range of materials and conditions. End mill cutter diagram.

Use cobalt PMPlus and carbide on harder materials and high production applications. It is possibler to gash a rougher on a tool cutter grinder or even a pedestal grinder with a hand-formed saucer. Made of solid carbide these end mills are harder stronger and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard material.

The overall reach of an end mill or length below shank LBS is a dimension that describes the necked length of reached tools. Such as Housingless Mill Stands 3Hi 2Hi Horizontal Stands 2Hi Vertical Stands Convertible Stands Sliding mill stands Universal Stands etc. CNC Milling Tools hot sale good quality use for.

Roughing End Mills - Carbide Cobalt and HSS. Some end mills with fewer flutes are called roughing end mills as the fewer flutes mean. The neck relief allows space for chip evacuation and prevents the shank from rubbing in deep-pocket milling applications.

Drill A tool for drilling. It is measured from the start of the necked. More on this Product Distributors Order Online.

End mill A multi-functional tool which has cutting edges on the periphery and an end face. When the Going Gets Rough NDC Gauging Systems Deliver. They are mainly used to rough mill the material off when large amounts of material are removed.

HSS 4 flute wave edge end mill norm table. This results in lower cutting pressures at a a given radial depth of cut. 3 flute metric end mill for aluminum offered in uncoated styles or with Zplus coating which smooths the end mills flute v.

End Mill An Overview Sciencedirect Topics

Taper Ball End Mill For High Accuracy Rib Slotting Eb4hr Ath Moldino The Edge To Innovation Moldino Tool Engineering Ltd

A Full Immersion Micro End Milling Process And B Chip Thickness Download Scientific Diagram

Xcan 2 Flute Ball Nose End Mill 4 6mm Shank Cnc Router Bit Carbide End Mill Spiral Milling Cutter Milling Cutter Aliexpress

Discretization Of The Ball End Mill Cutting Edge A Scheme Of Cutting Download Scientific Diagram

How To Select The Helix Angle Of End Milling Cutter Meetyou Carbide

Solid Carbide End Mill Top Cut Enorm Emuge Franken Website

5 Cutter Workpiece Engagement Geometry Extraction For Ball End Mill Download Scientific Diagram

End Mills Cad Cam Engineering Worldwide

How To Select The Helix Angle Of End Milling Cutter Meetyou Carbide

Roughing End Mill Kyocera Unimerco

Cutting Force Model For Helical End Mill Download Scientific Diagram

Ball End Milling Cutter Geometry 16 Download Scientific Diagram

End Mills With Diameter 20 Mm For Milling Experiments A End Mill With Download Scientific Diagram

Hpmt Sc Roughing Endmill G6110 Kyocera Unimerco

Geometrical Parameters Of An Endmill Download Scientific Diagram